Simón Bolívar Hydroelectric Plant: Maintenance of Gate Systems. Guri

1 de August de 2008

Simón Bolívar Hydroelectric Plant: Rehabilitation of the floating gates of the spillway, guri.

25 de June de 2011

Simón Bolívar Hydroelectric Plant: Maintenance of Gate Systems. Guri

1 de August de 2008

Simón Bolívar Hydroelectric Plant: Rehabilitation of the floating gates of the spillway, guri.

25 de June de 2011Simón Bolivar Hydroelectric Plant: Rehabilitation of the spillway channels, Guri.

The National Electric Corporation "Corpoelec" awarded FAPCO Hydro the contract for the rehabilitation of two spillway channels of the Simón Bolívar hydroelectric complex, located in Guri a Fapco.

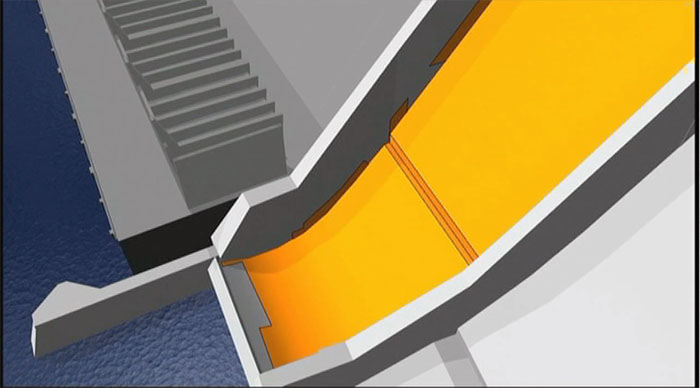

The spillway has a capacity of 27,000 m3 / s and has been in service for more than 40 years. It is subjected to the environment and the flow with cavitation of the water on the concrete during its operation.

FAPCO Hydro proposed using hydro demolition with a high pressure water jet to selectively remove weakened and damaged sections of the concrete landfill, leaving a rough surface ideal for bonding between existing concrete and the high strength mix needed for repair. Demolition with a pneumatic hammer would leave fractures and micro cracks in the concrete, compromising the quality of the work in the medium term.

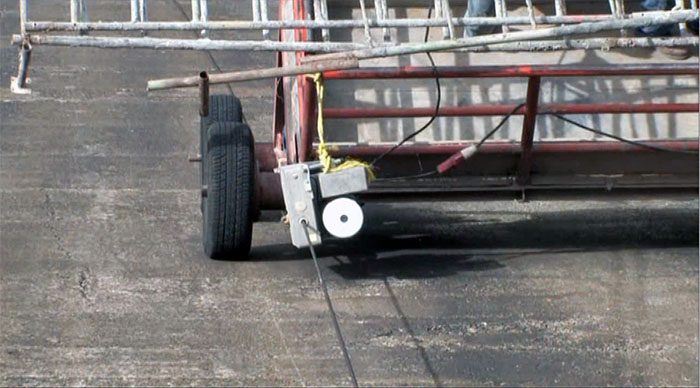

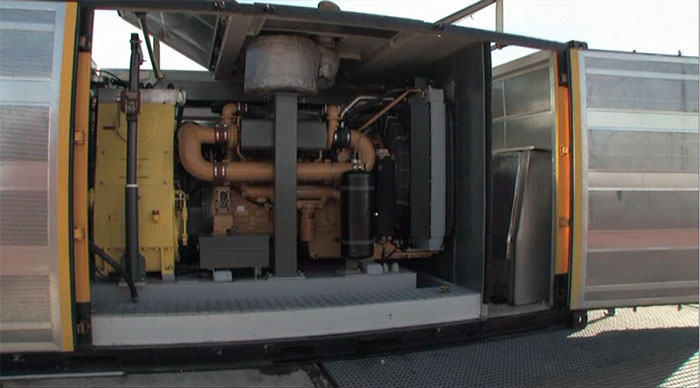

Fapco Hydro built a specially designed mobile platform to adapt to the geometry of the spillway channels, which have an average slope of 51 ° incline, equipped with winches attached to the crest of the dam that allowed it to move. A high-tech Conjet Robot 364 hydro-demolition equipment was installed on the platform. The robot operates at water pressures of up to 1,200 bar, demolishing weakened and damaged concrete from the spillway surface at depths ranging from 20 mm to 150 mm and in some cases exposing the steel reinforcement.

After the removal of the concrete, Fapco poured the restitution concrete with 800 kN / m2 mortar spray applied in areas less than 100 mm deep and 500 kN / m2 of concrete in the deepest areas.

The area repaired covered a total area of approximately 7,500 m2.

The repair system developed by FAPCO Hydro provides a proven and efficient mechanism for maintaining the spillways of large hydroelectric plants.

see video